Why choose LE UV printing?

Maximum efficiency, minimum energy costs and exceptionally beautiful printing. The LE UV offset printing press is a special piece of high technology that allows us, as a printing company, to go in all directions. But what makes this innovation so interesting for you and your printed communications? And for what projects is it best to use LE UV? A little synthesis!

Deadline stress? LE UV guarantees lightning-fast printing

Ink drying usually takes a long time. To speed up that process, on a traditional printing press we use a transparent varnish or blemish powder as an additional protective layer. With LE UV, this is no longer necessary. The ink dries at lightning speed. As a result, your printing will be ready much faster. We can start finishing immediately, resulting in shorter lead times and faster delivery times.

In addition, the LE UV printing press uses push-to-stop technology. As a result, the press operates almost fully automatically. Our printers have to intervene much less. We are able to keep printing continuously, which accelerates the whole production process.

More intense colors and inimitable image quality

The lightning-fast curing of the ink has another advantage: it eliminates the need for antismet powder, which also eliminates the risk of ink transfer to superimposed sheets. In addition, the ink is much less absorbed by the paper. Your printed matter will have much sharper and more powerful colors as a result.

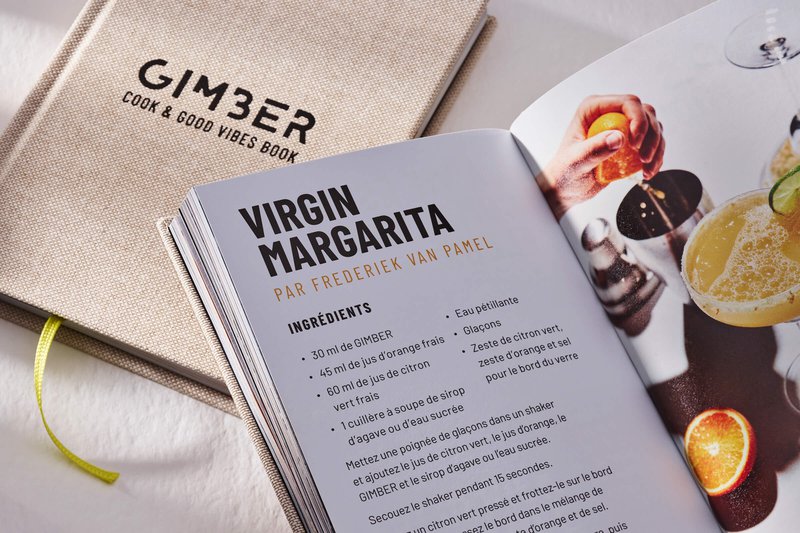

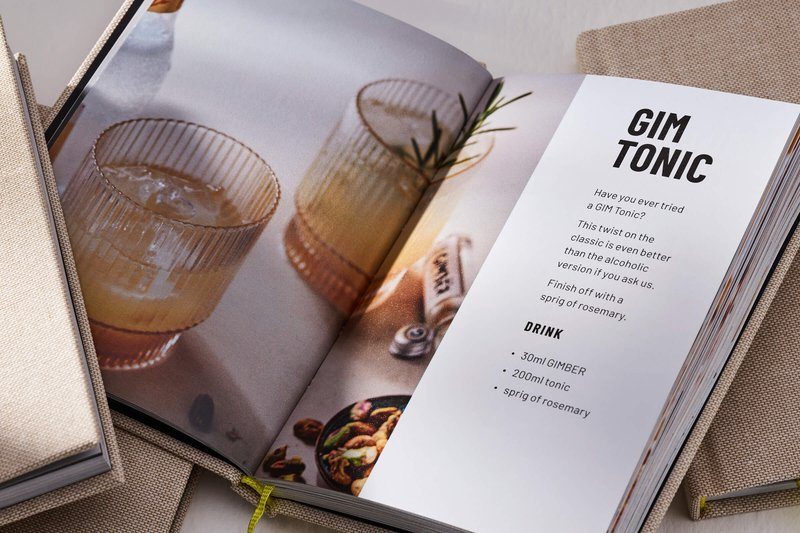

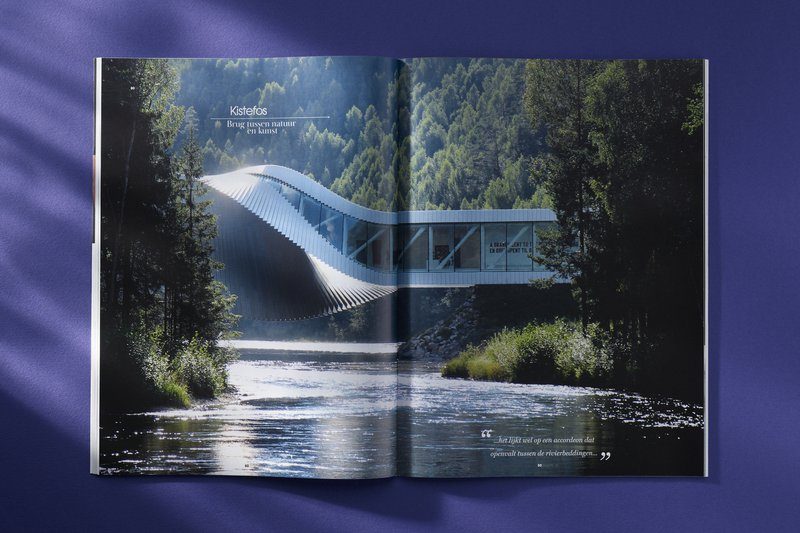

Printing clear images used to be especially challenging on uncoated paper. That absorbs quite a lot of ink, causing colors to lose intensity. Thanks to LE UV, things are different. We can now print on tactile, uncoated paper without sacrificing quality. Especially for a project with many photos, this is a huge asset. For example, do you want to have a catalog, art or photo book printed? Then you can expect unparalleled results. Thanks to LE UV, the images come out beautifully and you get printing of the very highest quality.

Environmentally friendly technology

At Buroform, we continually invest in environmentally responsible technologies and materials. The LE UV printing press is an investment that fits perfectly into our vision of sustainable business. LE UV stands for Low Energy Ultra Violet. Unlike traditional UV offset presses, ink curing is done using energy-efficient lamps with a carefully selected spectrum. In addition, the technology uses barely 2 cl of washing liquid per plate and, thanks to the standby function, requires up to half as much power.

In addition to energy and water, LE UV also saves on paper. The machine replaces, positions and checks its printing plates itself. As a result, up to 10 times less paper is required when setting up the press. So the inschiet – the number of sheets that end up in the trash during setup – is a lot lower. In other words, we need to purchase much less paper for each order. Because of current price increases, this means serious savings, not only for us, but also for you, the customer.

All the benefits again

Is your project suitable for printing with LE-UV offset?

Offset or digital? So which choice is most appropriate for your project? As such, there is no single answer. The ideal choice depends on very different things. Sometimes digital printing is still more interesting. Especially for small runs, it can be cheaper while the results remain very handsome. With large print runs such as books, magazines, catalogs and posters, the situation is slightly different. Then offset printing is a huge value-add for the reasons we outlined above. LE UV’s print quality is simply second to none!

Ready for your own printing project at Buroform? Connect with us through Sarah or Kelly.