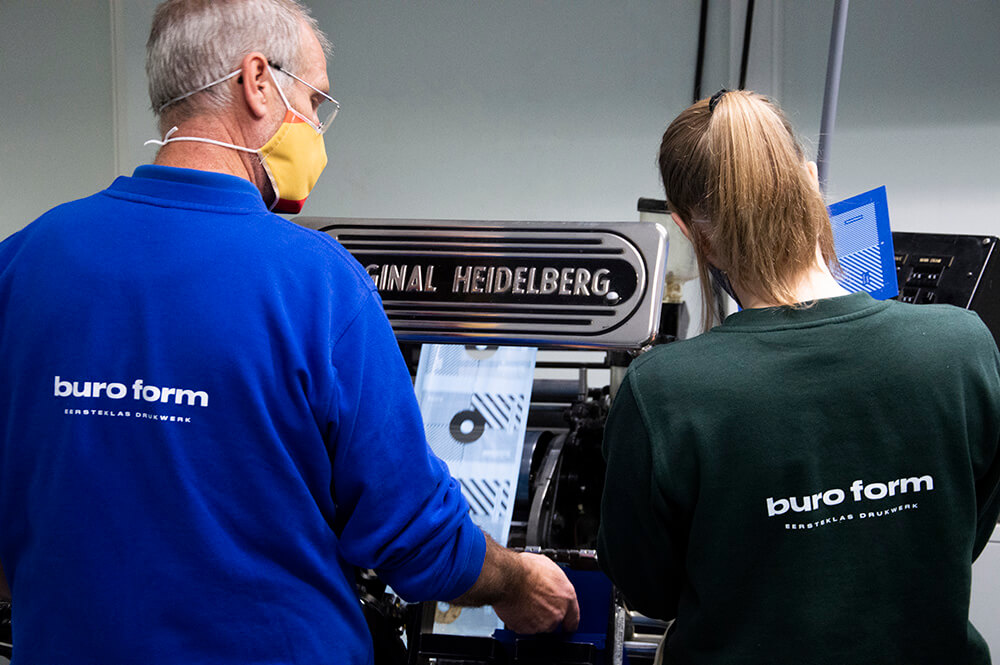

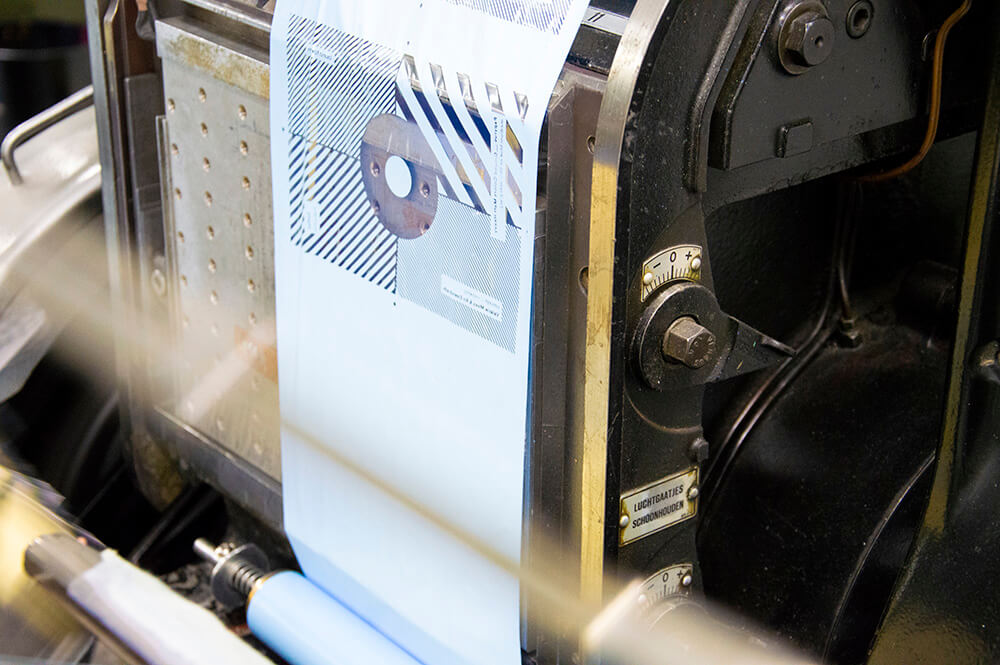

Letterpress is the official English name for letterpress, an artisan printing technique that is now five centuries old and has been fully revived in recent years. It is the predecessor of foil printing, where ink is used in place of foil to transfer the print image to the carrier (usually paper). Sometimes people also speak of type printing or relief printing, names that in turn refer more to the process behind them. This is because with letterpress, a tactile relief is printed into the paper.

It used to be done with wooden or lead letters that were first set by hand and then printed. Nowadays we use a cliché, a kind of printing stamp that we forcefully press into the paper using ink. A deeper print is created that gives your printed matter a very tangible character. Moreover, letterpress also paved the way for derivative techniques such as foil printing, blind embossing and intaglio.