How is a cliché created?

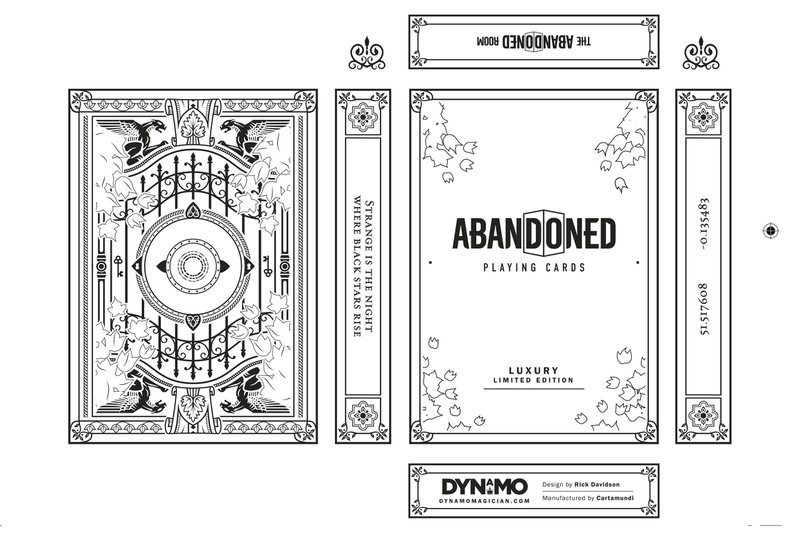

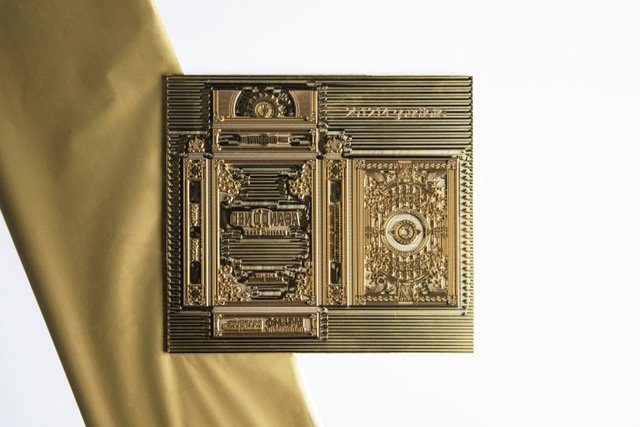

Foil printing adds a very nice shiny touch to your printing. But no foil printing without a cliché, a brass template used to press the desired text, shape or drawing into the paper. How does such a cliché actually come about?

Like just about everything these days, clichés – or stamps – cannot really be lumped together. You have them in different materials, manufactured using different processes and techniques. However, the most commonly used are clichés in etched magnesium and brass, the latter being particularly popular. “A brass stamp is very easy to bend to your will,” says Rosita Van Unen of Repro Hermans, specialist on duty in Rotterdam. “You can edit those in great detail and adjust them almost endlessly until you get the desired effect.”

From black and white PDF to engraving file

Within the product range in brass, Repro Hermans distinguishes foil stamps (the standard cliché for shiny foil), embossing stamps (bring relief to your printing) and foil embossing stamps (combine both techniques). Rosita Van Unen: “The basis of the creation process is always the same. We receive a pdf from the customer that we import into a special engraving program. That pdf must be black and white, otherwise the system will not accept it. If it is colored anyway, we adjust the color. The same goes for files with different encoding. We also have to convert them to the correct format first. So starting can be very easy, but just as well you have some work in Adobe Illustrator first.”

A brass stamp can be molded to your liking very easily. You can edit those in great detail and adjust them almost endlessly until you get the desired effect.

Engraving with CNC machine

In the engraving program, Rosita creates a simulation of the cliché. It is important to consider what milling size the actual machining will be done with. “Let’s assume a 0.1mm cutter,” she says. “Then we must first see which parts are large enough to engrave with the CNC machine and which are too small. Some details require such minute treatment that additional processing with the laser is necessary. Were we not to do that, we run the risk of an upset result. So we select the smallest parts of the file that the cutter can’t go through and transform them into a laser file.”

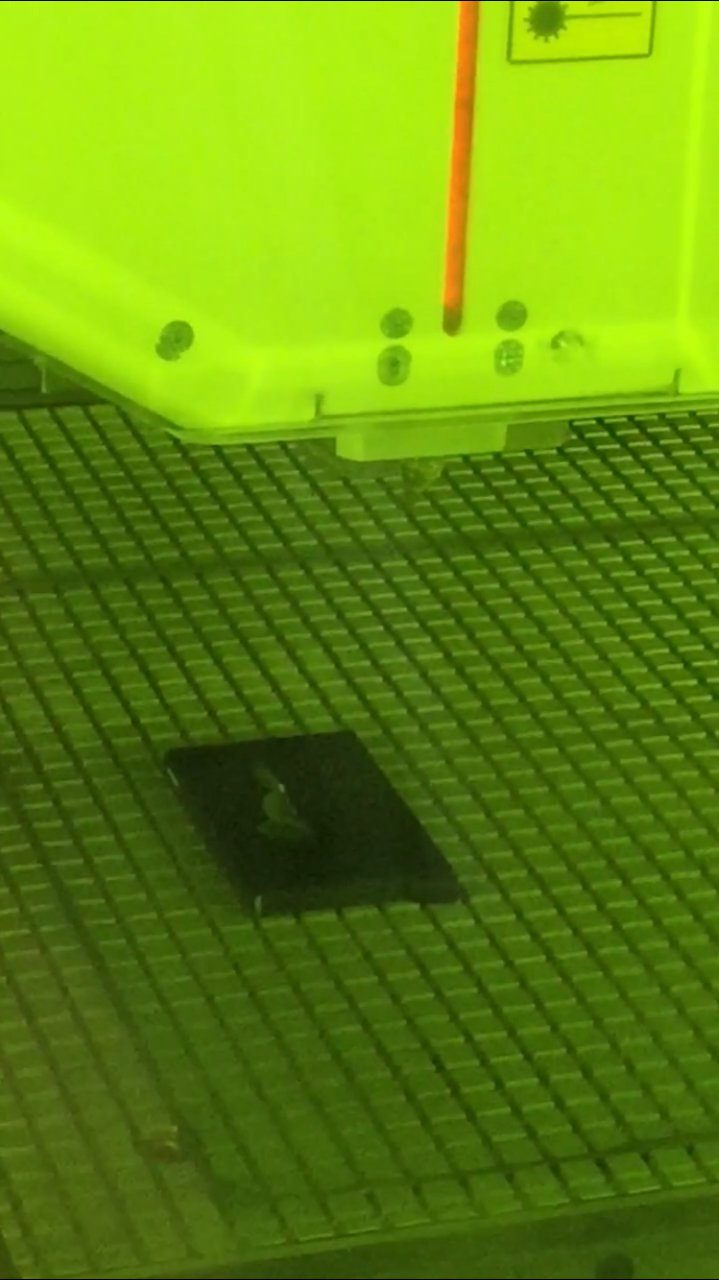

Lasering for additional refinement

The cliché is first engraved with the CNC machine, as fine as possible. “In some cases, this step is sufficient. In the case of a very detailed file, we then move on to the laser machine. There we engrave the stamp again, so that even the very finest particles are burned away. Actually, you should engrave the entire file that way. That would be the most beautiful thing. But that is not desirable, not for the customer and not for us. The laser burns away microscopic pieces of 0.02mm per focal point. If you make a cliché that way, you’re easily two weeks away. I don’t think anyone wants to pay that cost.”

The laser burns away microscopic pieces of 0.02mm per focal point.